DOWNSTREAM PROCESS DEVELOPMENT SERVICES

Home » Process Development » Downstream process development services

FINDING SOLUTIONS THAT ENHANCE PROCESS QUALITY

We routinely deal with a variety of expression systems. Our special strengths include protein refolding expertise that has been finely honed by years of project experience.

We can adjust and fine-tune the steps of downstream process development to meet your needs. This includes complete DSP development from scratch and/or DSP adaptation and optimization studies. Our general downstream process development services can include:

- A process design phase

- An intermediate process scale-up

- A process engineering/adaptation phase

- Process reproducibility studies (e.g. for scale-up purposes and/or preclinical animal studies etc.)

WIDE RANGE OF TECHNIQUES

At Richter-Helm BioLogics, a large arsenal of cutting-edge purification techniques is available for DSP development for large-scale biomanufacturing. The use of small-scale equipment facilitates the development and optimization of downstream processes based on:

- Cell disruption, IB isolation

- Protein extraction, protein refolding

- Chromatography

- Resin scouting

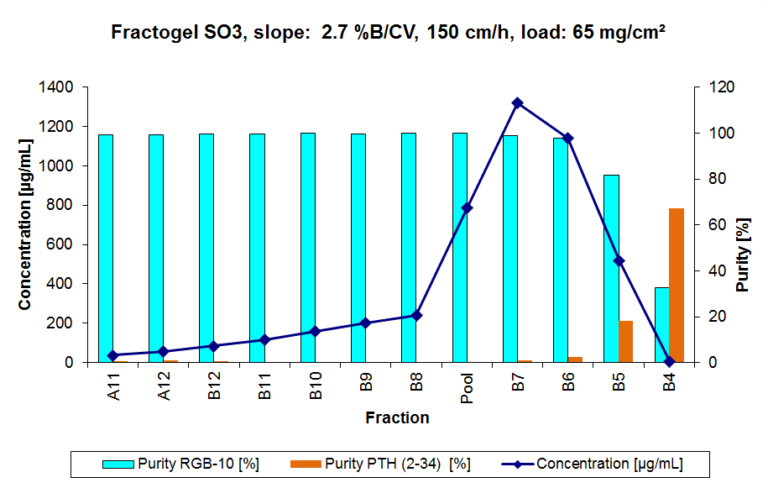

- Chromatography parameter screenings

- Testing of product elution in step or gradient mode

- Conditioning, e.g.

- Titration, precipitation

- Clarification (centrifugation, dead-end filtration)

- Crossflow filtration (cassettes and hollow fibers)

In a multistep approach (with capture, intermediate purification, and polishing), we can use state-of-the-art chromatography techniques (in FPLC or HPLC mode) including:

- Anion or cation exchange chromatography

- Mixed mode chromatography

- Hydrophobic interaction chromatography

- Reversed phase chromatography

- Affinity chromatography

- Desalting and/or size exclusion chromatography

TOOLS FOR R&D MONITORING

All of these development tools can be used to identify the best fully scalable downstream process design for efficiently purifying your product.

In addition to QC testing, rapid at-line PD analytical tools can be employed at any point of the development phase. These include:

- UV/VIS spectrometry

- AGE, PAGE/WB, and HPLC

- Turbidity, DLS, nano-DSF, and endotoxin measurement

Design of experiment (DoE) tools (applying full or fractional factorial design modules) are routinely used to assist in developing and optimizing processes or, if applicable, to supplement parameter screenings etc.

This might interest you

We offer you our strong expertise in developing strains based on E.coli host systems to produce peptides, proteins (soluble and insoluble), plasmid DNA products, and vaccines.

Find Solutions that enhance process quality. USP and DSP teams work hand-in-hand to speed up process development and make every project a success.

Richter-Helm BioLogics operates two multipurpose facilities for manufacturing biological drug substances with microbial expression systems.