PROCESS CHARACTERIZATION SERVICES

Home » Process Development » Process characterization services

UNDERSTANDING PROCESSES IS ESSENTIAL

We establish scale-down models for fermentation concepts, chromatography, tangential flow filtration (TFF), etc. for (among other things):

Proven acceptable/normal operation range (PAR/NOR) studies for USP

- Temperature, DO, pH seed / main

- Feed rates / growth rates

- Induction point / OD, induction temperature / inducer titer

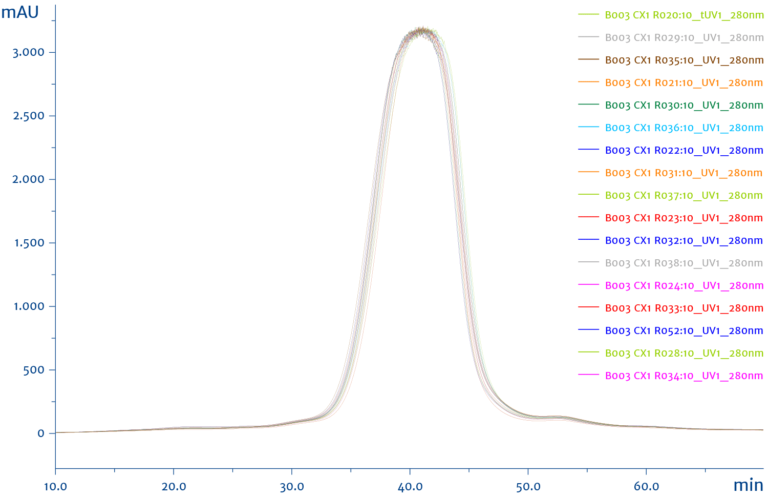

Proven acceptable/normal operation ranges (PAR/NOR) studies for DSP

- Dynamic resin binding capacity, ligand density (chromatography)

- Bed height, gradient slope, flow rate (chromatography)

- Membrane load, TMP, concentration / diafiltration factors (TFF)

We establish scale-down models for fermentation concepts, chromatography, tangential flow filtration (TFF), etc. for (among other things):

- Lifetime studies

- Resins/columns

- TFF membranes (cassette/hollow fiber)

- Impurity removal studies of

- Process-related impurities like antifoam agents, host cell proteins, host cell DNA, etc.

- Product-related impurities like product isoforms (oxidized, deamidated, truncated, forms, etc.)

The findings can flow into risk assessments and/or process control strategies and/or process validation studies. This additional knowledge can then be applied to improve process robustness and product safety while production is being scaled up to serve the market.

This might interest you

We offer you our strong expertise in developing strains based on E.coli host systems to produce peptides, proteins (soluble and insoluble), plasmid DNA products, and vaccines.

USP and DSP teams work hand-in-hand to speed up process development and make every project a success.

Richter-Helm BioLogics operates two multipurpose facilities for manufacturing biological drug substances with microbial expression systems.